Concrete stave silos are constructed using precast concrete blocks, or staves, that interlock. Stave silos are reinforced with exterior, galvanized steel hoops which help compress walls and provide the necessary tension for structural integrity.

When it comes to the structural integrity of your concrete stave silo, it’s important to look at the condition of the exterior wall and the exterior steel hoops. When inspecting your stave silo, you want to look specifically for cracks in the staves or bulges in the wall.

If you see cracks in the staves, you need to decide what kind of crack you’re seeing. Here are the types to look for – horizontal, vertical, or diagonal cracks – or more severely, when you see an offset and it appears the wall is starting to move. The upper wall is pushing out over the lower wall above a horizontal crack.

If you have a crack and it’s starting to move and expand, this is a sign of silo failure and it’s time to call in the experts.

It’s equally essential to look at the exterior steel hoops because they maintain the structural integrity of the silo; their stability is vital to the health and safety of the silo. The exterior hoops shouldn’t be bent, broken, falling off or lying on the ground. It’s also important to make sure the hoops aren’t heavily corroded. Hoops are bolted together with a lug and the lug can be problematic if it beings to corrode. The hoops are tensioned to a specific rating and pressure so it’s essential that the hoop has not been welded to and stands independently.

One of our recent case studies examines a cracking stave silo and provides further proof on the importance of keeping a proactive maintenance schedule which includes inspecting your silo regularly. Silo inspection is the most effective, preventative method to ensure the integrity of your concrete stave silo.

To learn more, be sure to check out our full library of silo inspection videos on silo maintenance, inspection and repair on

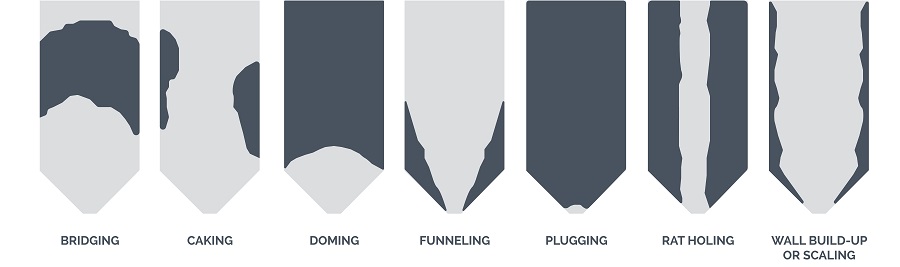

No matter the design or the materials stored, silos are susceptible to material flow issues caused by blockages. Buildup in the silo is an indication of ratholing and potentially asymmetric flow, which can increase pressure loads inside silo walls. When you have buildup in the silo, the loads associated with asymmetric flow can be detrimental to the structural integrity of the silo as they can lead to wall failure and total silo failure.

Material flow that is unimpeded by blockages is essential for smooth operations and the continued functionality of your silo. Blockages not only promote bad flow characteristics, but also lead to a reduced storage capacity.

You can help reduce the likelihood of material buildup through a number of ways. Depending on how easily stored material compacts or hydrates, your silo may need to be completely emptied on a regular schedule as often as once a month or as little as every year.

Cement Silos

To prevent stored cement from setting inside the silo, the structure must be completely watertight. Even pinhole leaks in silo roofs and walls damage your stored materials and can result in blockages and material flow issues. Ambient humidity levels can also cause some materials to set. If you do aerate stored materials, it is important to use air dryer systems to help lower the ambient humidity level in the silo. You should also avoid over aerating stored materials. Excess aeration can pump unneeded moist air into the silo which may lead to hydration of the cement.

Essential maintenance includes exterior waterproof coating(s) and keeping your air pad and air stones in good operating condition. Completely emptying your silo frequently is also important as it helps prevent compaction of stored materials.

Fly Ash Silos

It is important to keep the fly ash cool as it is loaded into the silo. Make sure your ash does not include unburnt carbon material as this can lead to material buildup along the silo walls. Chemicals from pollution control chemicals can cause your ash to become cementitious, or sticky. Coal from the Wyoming Powder River Basin is also inherently cementitious in nature. Cementitious material leads to asymmetric flow. Learn more about Fly Ash Silos.

Maintenance Schedules

It’s essential to have a proactive silo maintenance schedule, ensuring continued, safe operation.

While professional inspections are recommended every two to five years, unless there are structural or operational concerns that would necessitate more frequent inspections, frequent in-house inspections will verify that preventive maintenance measures are being followed. Silo maintenance should include regular checks of airflow units, a routine professional cleaning, and regular, complete silo emptying. Of these measures, one of the most important is the regular emptying of silos.

Silos that are regularly emptied and refilled are less likely to experience buildup issues seen in those kept topped off. Regularly emptied silos need professional cleaning less frequently in comparison. They are also less likely to experience issues like compacting and hydrating. Hydration occurs when moisture mixes with stored materials and causes them to solidify within the silo. When this happens, materials can expand and cause added wall pressure which increases the likelihood of structural failure.

The routine examination of your silo is only effective in increasing facility safety and ensuring smooth operations when it is conducted in conjunction with professional inspections (and cleaning services) as part of a regular preventive maintenance schedule. A recent case study provides an example of how asymmetric flow can cause silo failure.

To learn more, be sure to check out our full library of silo inspection videos on silo maintenance, inspection and repair on